A New Ferris Wheel Rises at Navy Pier

I’ve documented many construction sites over the years, but heelatching Navy Pier’s new Ferris wheel rise has been one of the most unique and exciting experiences. In this blog post, I detail some of the technical aspects of building the new Ferris wheel, and will update you with periodic photo updates of project milestones and advancements as I capture them.

First thing’s first: The new wheel was built by Dutch Wheels, engineered by Thornton Tomasetti, and assembled by a multi-national crew, including Chicago’s own McHugh Construction. It will stand a total of 200 feet tall; 54 feet taller than the old wheel. The 42 gondolas, capable of holding eight to ten passengers each, will ring the rim, and the entire structure will weigh a massive 1,000,000 pounds! The previous wheel weighed less than half of that at 485,000 lbs.

Building a Ferris wheel of this magnitude can be challenging, but building one on Navy Pier is exponentially harder. As I mentioned before, the new wheel weighs more than twice that of the old wheel. Keep in mind, the Ferris wheel sits atop the roof of a parking garage, and Navy Pier itself is built atop a bed of 20,000 wooden pilings shallowly sunk into the lakebed. In order to hold the structure’s weight without damaging the Pier’s foundation, additional supports were necessary.

To solve the problem, eight micropiles (thin, high-strength concrete support columns) were sunk over 125 feet directly into the bedrock beneath Lake Michigan. These micropiles would direct most of the Ferris wheel’s weight into solid ground and take the stress off the Pier. Concrete shear walls were added to the weight-bearing garage columns to support additional lateral loads. Once all of that work was done and the concrete was cured, the main structure could be assembled – and I was able to come back to capture the action.

My updates are below in reverse chronological order.

The Ferris Wheel Opens | May 27

Well, the Ferris Wheel is finally done. It was a long day of shooting, and waiting through a thunderstorm, but after months of work and thousands of photos, it was great to photograph the complete structure. Here are some shots…

Mini-update from above: Aerials | March 14

I took to the skies for an aerial perspective of annual St. Patrick’s Day dyeing of the Chicago River. While waiting for the dye to get well churned and mixed, we took a short detour and did a couple orbits over Navy Pier to get a few shots of the new Ferris wheel.

Phase Three: Gondolas | February 29

After the Ferris wheel’s main structure was complete, work slowed on-site for a couple weeks. As the crew awaited the arrival of the gondolas, a lot of behind-the-scenes work was going on. Among other things, connections were tested and tightened, and cables and wiring were run to power the wheel. A total of 42 gondolas will ring the rim, and each one is capable of holding eight to ten passengers. There’s even a special VIP gondola with a clear glass bottom – but that one can only hold four passengers.

Installing the gondolas is a fairly quick process. In fact, the crew was able to hang all of the gondolas in a single day! Now, here are some photos…

When the gondolas were hung, the crew had to alternate sides to keep the wheel in balance. In the photo below, you can see four gondolas high atop the wheel, and a few more peeking out from behind the gondola in the foreground. After four gondolas were added, they rotated the wheel back down to add four more before repeating the process.

Phase Two: Spokes + Rim | January 29 & February 1

The process of installing the spokes and rim began about a week after the hub was put into place. In between that time, the eight drive motors were installed, along with additional ladders and support platforms. While the hard part was complete, the most drastic visible change would occur as the full circumference of the Ferris wheel was rounded out.

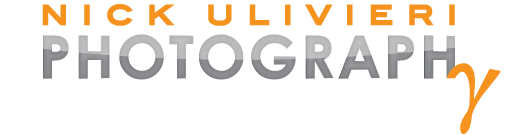

The finished Ferris wheel will have 21 spokes in total, while the old wheel had 40! Not only will this wheel be bigger, but it will appear much lighter with half as many spokes.

Each spoke is made up of six individual pieces, but arrived on site in two halves – top and bottom. The spoke weighs 9,000 lbs. and measures 91 feet in length. To install, the first half gets lifted into place via a pulley system (see the blue pulleys in the photo below) which connects a high-tensile wire to a winch on the support column’s footing. A small crane (the biggest ones have since left the project) then helped steady the bottom portion and kept it from swinging wildly.

This is where the fun begins – at least for the workers who aren’t afraid of heights. As the first half of the spoke approached the hub, two teams of workers hopped in their respective cherry pickers and ascended to the top of the structure to permanently join the spokes to the hub. But to actually get the bolts into place, they had to climb out of their bucket and onto the suspended spoke. If you’re worried, don’t be – These guys had on the proper fall arrest harnesses and were tied off to strong anchor points.

Once the first half was securely fastened to the hub, the final portion of the spoke was lifted into place and secured, and then a multitude of cross braces and tension cables were attached to ensure the spoke stayed rigid. This was a tedious, repetitive process so I wasn’t on site for too long after the third spoke was hung.

I visited the site again the following Monday to catch the spoke progress. Due to the impending weather system moving in, I wanted to take advantage of the blue skies and mild weather while I could. As usual, I parked on the roof of the West parking garage for the views of the city and partially constructed Ferris wheel.

After a few roof shots I ventured back down to the site for more images of the partially built wheel. Check out the photos from both spoke visits in the gallery below:

Phase One: Support Legs & Hub | January 19 & 20

I was on site in late October 2015 when the old wheel was disassembled (here are a few photos of that process). Between then and early January, a majority of the site work consisted of building and pouring the wheel’s foundation, but it was finally mite for the big show – raising the main supports and center hub. Because of the potential dangers involved with maneuvering such large pieces with heavy machinery, the Pier was closed to all visitors for two straight days – a feat in its own right. Since they had such a limited window of time, the lifting of the main supports and center hub had to take place regardless of conditions.

And those conditions brought some of the coldest temperatures of the season. Lucky for me, the challenge of photographing in frigid conditions has always been an oddly enjoyable one. Compared to past winters, the ~10 degree temperatures weren’t all that bad, but it is still challenging to shoot in. Particularly if you’re out in those elements for 5+ hours.

January 19th was the first lift day – and the coldest. I’m good at layering up, but the low temperature called for plenty of hand warmers, too. I also shoved some in my boots. Standing on cold ground all day will cut through warm boots and insulated socks quickly. Another tip – keep another warmed in a breast pocket and stash any extra camera batteries and your phone in there. Cold temperatures drain power from batteries and this will help keep them operating normally.

Cold weather aside, watching the highly choreographed movements of the cranes was astounding. I didn’t realize it at the time, but the cranes had to be in very specific positions to perform their lifts. Again, we’re on a roof, so the outriggers that support the huge cranes lifting the massive 33,000+ pound pieces needed to be centered near or on load bearing columns and beams. If one of the cranes was improperly positioned, it could have punched through the parking garage’s roof and jeopardize the whole project.

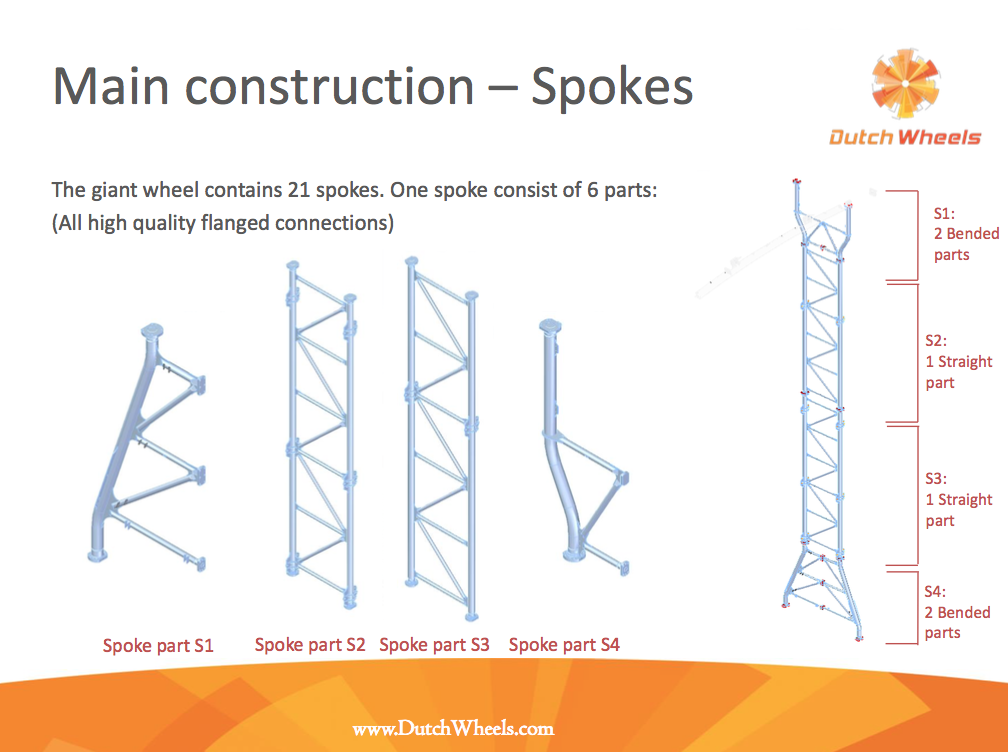

By the end of day one, two of the four main support columns were up, as well as the third outrigger beam that kept the two main columns in place – just under 50% there. Unlike the previous wheel which had eight support columns, the new one has only six. Similarly to the old Ferris wheel, four columns would support the hub. But with the new one, only two additional columns were needed to keep the mains in place. This feature has an added benefit of decluttering the park space and opening up the footprint around the wheel, too.

I was back at the Pier early the next day, and while it wasn’t quite as cold – a much more balmy 15-degree day – and there was a nice blanket of snow on the ground. I found this to be a rather interesting contrast. It was a total inverse of what you expect at the Pier. Instead of a crowded public way with a Ferris wheel spinning on an idyllic summer day we had this, which was beautiful in its own right, in my opinion.

While the remaining support columns went up rather smoothly, the star of the show was the installation of the central hub. Weighing in at 46,000 pounds, the hub is the heart of the Ferris wheel; it ties all of the columns together, allows the wheel to spin, and supports the spokes, outer rim and passenger gondolas. As late afternoon rolled around and the hub was ready for installation, the snow had moved out of the area and the sky was picture-perfect. After some wrangling and adjusting the main support was finished just in time for the Pier to fully open the next day – as anticipated.

Here’s a big gallery of images from the first two lift days.